Fine Beautiful Info About How To Build A Kart

Learn welding and fabrication with my $39 online courses:

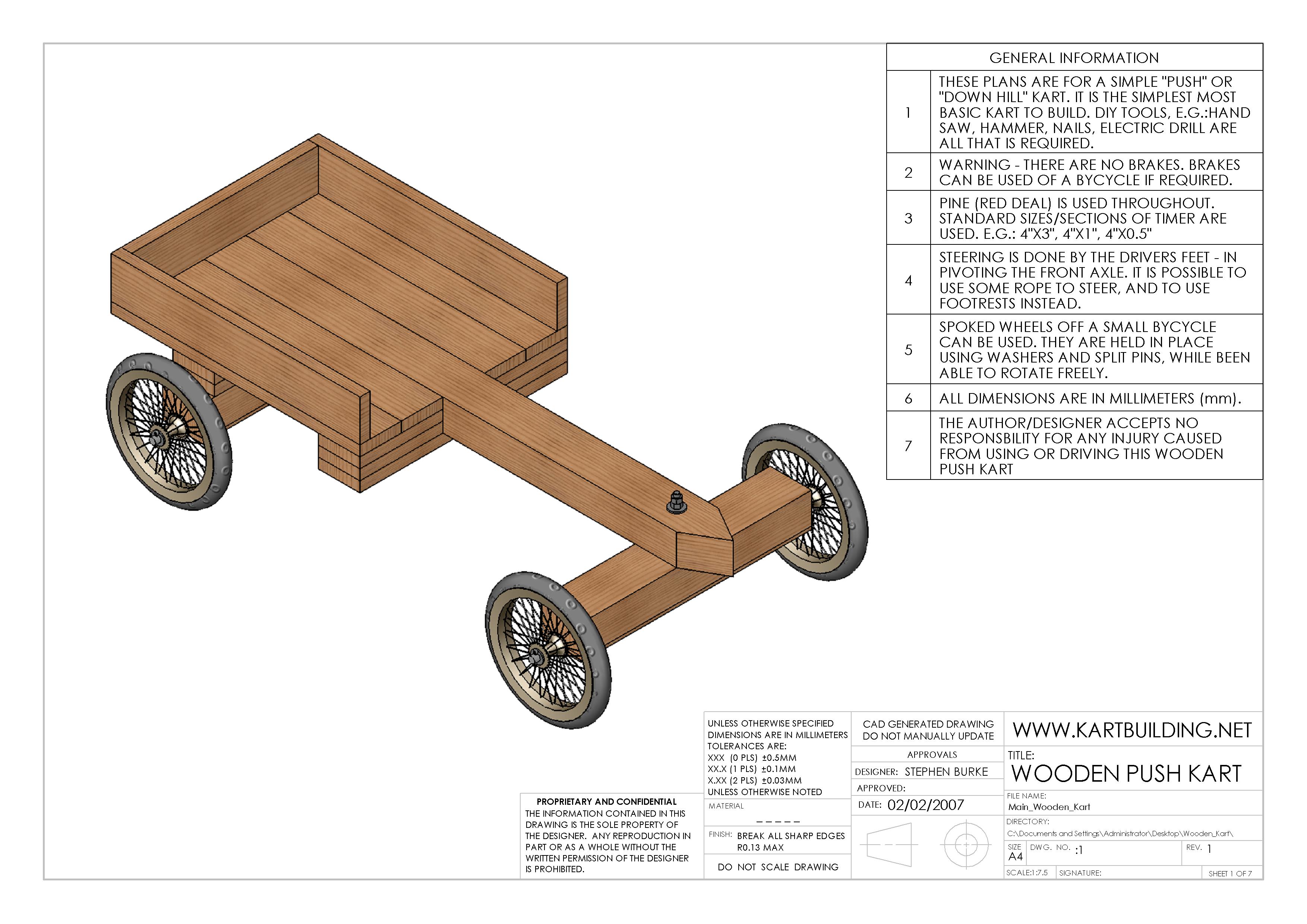

How to build a kart. The toe in should be set at 0 degrees or slightly toeing out 1or 2 degrees. The downhill wood pro go kart project 3. Before welding each piece, make sure to measure its length and width.

Then lay the metal tubes in front of you on a table or a stable surface like a concrete floor big enough to accommodate the frame. Diy simple wooden go kart. No matter what frame design you have, make sure the size correctly matches the driver’s size.

Clamp the steel in a vise and file or grind the cut. Next, you need to gather the necessary parts; Building the kart yourself means you get to choose what to build it out of.

This includes the frame, wheels, and body parts. Getting the materials, involves either scrounging around and finding materials, or buy them from. Cut your lengths of tubing to the appropriate lengths, given your design or schematics.

Although the plans maybe somewhat old (coming from the may 1962 edition of modern mechanix), the information and details provide an excellent insight into kart design, building and racing. Motor, axle, steering wheel and tires/wheels for construction. Place the steel pipe on a clear area of your floor.

Draw it on a sheet of paper, then transfer it to a larger sheet so that all dimensions are exact. Make a jig for your kart (optional). First is to design the frame.

Your pieces should all be laid out and labeled. The rubber bumper go kart. The kid’s electric retro vintage go kart blueprint 5.

Only a couple of thinks left to do reassemble the kart, and then check everything before you go racing, things to check include. A jig is a flat piece of metal with slots for clamps to hold down the tubes. We’ve compiled a list of commonly used materials.

It is sure to impress anyone and provide countless hours of fun for the whole family. Step by step assembly. Mario kart 8 deluxe has been a smash hit for a decade, but new games in the series typically innovate.

Remember, the key to a successful build is preparation. Building the chassis and steering column 1. You have to design everything for it to work out in the end.